It’s estimated that by the end of the decade, electric vehicle sales will drive lithium demand to five times its current level. That sudden increase has companies looking for new sources of the valuable metal, but one scientist at the Pritzker School of Molecular Engineering at the University of Chicago believes we have all the lithium we need, and it’s waiting just off shore.

Currently, about 75% of the world’s lithium comes from a mountainous stretch of land straddling Argentina, Bolivia and Chile, an area called the Lithium Triangle. There, the metal is extracted by pumping brine into giant open-air basins where it’s evaporated over the span of a year. However, that lengthy process presents a major bottleneck in a lithium-hungry world, and while other sources do exist, most come at an environmental cost.

To prevent the looming shortfall, many countries, including the United States, are searching for sustainable extraction methods for the in-demand element. That’s where Chong Liu, Neubauer Family Assistant Professor at the Pritzker School of Molecular Engineering, comes in.

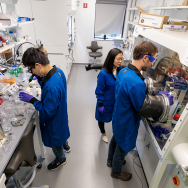

Liu is a materials scientist—she studies the properties of matter in order to create highly specialized materials. Currently, her lab is developing a new type of electrode that can extract valuable elements from seawater using a process called electrochemical intercalation. And while Liu’s work is still in its early stages, it could present one of the most sustainable methods for extracting lithium anywhere.

“Our big motivation is to create a process that’s as environmentally friendly as possible,” Liu said. “Since we are taking an electrochemical approach, we completely avoid the need for intense heat or strong acids, and we get only the element we want—that’s single ion selectivity.”

That approach is one the U.S. Department of Energy is taking seriously. On Sept. 2, Liu was named one of 13 researchers to receive part of a $30 million fund aimed at securing the nation’s critical materials supply for clean energy technologies.

“Expanding electric vehicle infrastructure, hardening our nation’s electrical grid, and powering our economy with millions of clean energy jobs all rely on securing supply chains of critical materials like cobalt and platinum,” said U.S. Secretary of Energy Jennifer M. Granholm. “The key to our carbon-free future lies in ramping up clean American industries, building strong supply chain systems of American-made critical materials, and aggressively deploying the resulting climate technologies here and abroad.”

The electrochemical approach

To understand Liu’s method, it’s helpful to imagine an electromagnet. Similar to how an electromagnet can attract and collect ferrous metal, Liu’s process can attract and collect lithium. There’s no magnetism in electrochemical intercalation—instead, the ions are attracted by an electrical field—but the principle is similar. Workers would be able to submerge an electrode array into a pool of seawater, attract the lithium, and then release the collected lithium into a storage tank.

On the molecular level, Liu achieves this by designing highly specific electrode materials that draw ions towards the electrodes while only capturing certain elements, trapping them.

There are challenges to this approach, though. Because lithium concentration in seawater is quite low, about 0.2 parts per million, any extraction technique will need to be extremely efficient in order to pull out lithium at a reasonable rate. Also, in order to use these electrodes on an industrial scale, they’ll need to be made of highly selective, highly durable material. Choosing the best candidate for that will take time.

Liu understands those challenges and she’s accounted for them at the design level. Her lab has already seen promising results in the material selection process, narrowing down candidates to a few likely families, which she is working to refine further with new machine learning techniques. It’s her hope that within the next decade there will be a new, fully sustainable system for extracting lithium.

“I fully expect that within 10, 20 years we’ll see a complete transformation in how people and goods are moved,” Liu said. “But to create that, to address climate change in a serious way, we need to find environmentally friendly methods for every aspect of that process, including battery manufacturing. That’s what we are hoping to provide.”

—This story was first published by the Pritzker School of Molecular Engineering.